Ultra Pure Water

Ultrapure water by MPure™ electrodeionization system

Did you know?

The conductivity of ultra pure water can be up to 0,055 µS/cm at 25℃, also expressed as the resistivity of 18,2 MΩ∙cm.

Ultra Pure Water

Ultrapure water for green hydrogen production

Find out how MEGA's electrodeionization can help you with (not only) green hydrogen production

Electrodeionization increases sustainable hydrogen production by reducing operating costs through higher water yield. This is achieved without the need for column regeneration chemicals!

MEGA provides ultrapure water treatment technology for the production of green hydrogen that meets strict water quality criteria for use in electrolyzers, typically <1 µS/cm. The ultrapure water produced meets the demanding quality requirements for advanced hydrogen production. Expressed as an electrical conductivity of up to 0.055 µS/cm at 25°C or as a resistivity of 18.2 MΩ∙cm.

If you are experiencing problems with water for your green hydrogen project, we are happy to help.

Learn about our solution for producing ultrapure water for green hydrogen production

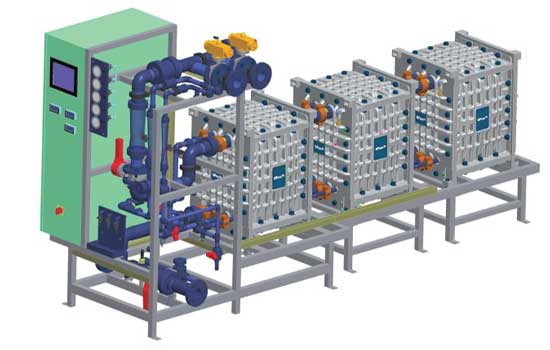

Ultrapure water system by MPure™ electrodeionization

Products and services for Ultrapure Water production by MEGA

Our ultrapure water projects

ENERGY AT ÚSTÍ NAD LABEM, CZECHIA

Rehabilitation and upgrade of process water treatment plant using UPW

Read moreMEGA has supplied High Purity Water Treatment EDI units as a part of a novel membrane-only water treatment solution. The facility in the company ENERGY in Ústí nad Labem, Czech Republic, needed an upgrade after decades of heavy-duty.

Ultrafiltration, reverse osmosis and EDI units were selected to process river water into ultrapure water. MPure™ EDI by MEGA has proven to be able to operate in demanding conditions with high CO2 level, cope with differences in input feed and steadily provide the heating facility with the ultrapure water with 16 MΩ resistivity. Contact us below to find out how a similar solution can help your business.

ENERGY highlights

Termozipa at Tocancipa, Colombia

Modernization of process water treatment plant using high purity water

Read moreMEGA has supplied continuous electrodeionization RALEX® HPWU as a part of a new process water treatment plant in the coal power plant TERMOZIPA in Colombia.

Due to the current outdated and unsatisfactory solution of the process water treatment, which could no longer process the required water capacity, TERMOZIPA has decided to build up a completely new water treatment plant. MPure-EDI from MEGA was selected to achieve ultrapure water as a part of the pretreatment system along with ultrafiltration and reverse osmosis technology. MEGA UPW technology ensures the continuous quality of the ultrapure water with 18 MΩ resistivity.

TERMOZIPA highlights

Request a free quotation for your Ultrapure water (UPW) project

Our experts are ready to find the best solution for your EDI ultrapure water project.

Please, fill out the form below. We will reach out to you as soon as possible.

Interested? Contact us.