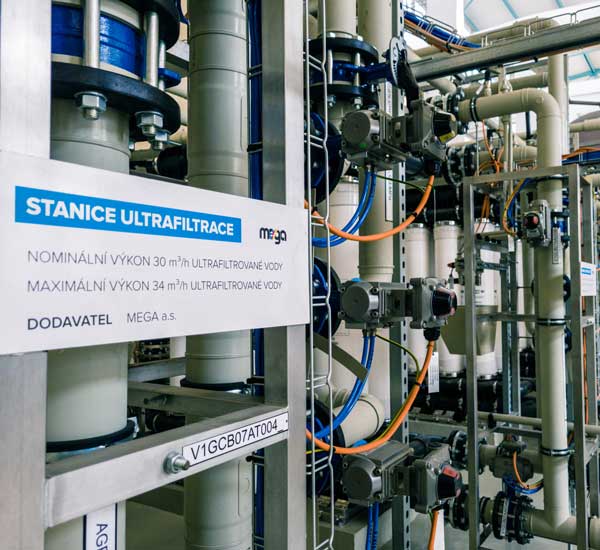

CLASSIC Oil s.r.o., the largest Czech manufacturer of coolant/antifreeze and heat transfer fluids, has been using the unique RALEX® ART electromembrane technology from MEGA since 2017. It is used to process the glycol solution for its subsequent recycling. Coolants, antifreeze and HVAC fluids are recycled by electrodialysis and can be reused to produce new coolant fluids. At the same time, the innovative nature of the recycling process is more nature friendly, where the glycols saved do not burden the environment and also reduce the amount of waste produced.

In 2019, 100 tons of waste material was recycled thanks to this technology. For every 1,000 litres of waste material, 900 litres of pure product is produced that meets strict ASTM standards.

Ask about this project